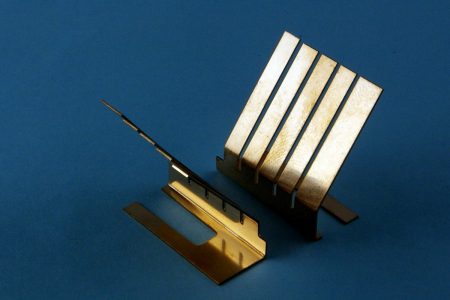

Industry: Electrical Controls

Function: Coin Detector

Material: Alloy 510 Grade A Phos Bronze Spring Temper

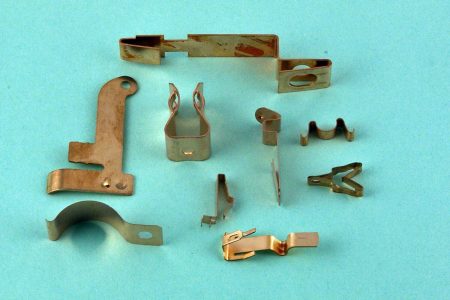

Industry: Electrical Controls

Function: Contacts

Material: Beryllium Copper, Phosphor Bronze

Industry: Appliance

Function: Tube Support

Material: Type 1 Aluminized C1008 Steel

Industry: Liquid Dispensing

Function: Trip Finger

Material: .012 Thk T302 Spring Tempered Stainless with a Skived Round Edge

Industry: Appliance

Function: Tube Connector

Material: .134 Thk C1008 Steel with a Deburred Edge

Industry: Appliance

Function: Handle

Material: C1008 Steel with a Round Edge

Industry: Material Handling

Function: Wire Rope Guide

Material: C1008 Steel

Industry: Electrical Distribution

Function: Counduit Clamp

Material: .125 Thk C1008 Steel

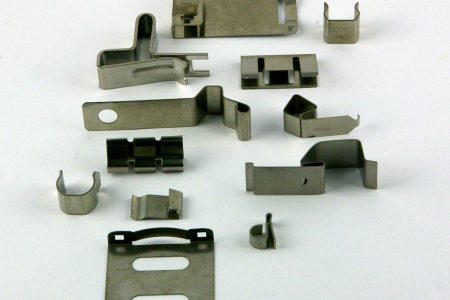

Industry: Various

Function: Various

Material: C1008 and C1074 Steels

Industry:Consumer Electronics

Function: Ground Contacts

Material: T301 Stainless 1/2 – Full Hard Tempers

Industry: Processing

Function: Clamp

Material: .060 Thk 301 1/4 Hard Stainless

Industry: Processing

Function: Spring Clip

Material: 17-7 PH Stainless Condition C

At Wm Dudek Manufacturing we specialize in manufacturing top-of-the-line four slide products including flat metal spring clips, spring steel clips, stainless steel clips, and metal spring clips and clamps. Each of these applications can be used in a wide variety of industries from appliance manufacturing and electronics to material handling and liquid dispensing.

When it comes to ensuring your fourslide parts are produced quickly, efficiently, and in the most cost-effective manner, there’s nothing like our shop. We work with some of the world’s leading OEMs and can easily produce runs of thousands of parts including spring steel clips and flat metal spring clips. Need precision metal springs and clamps? We do that, too. Fourslide machining is an ideal process when you need precision parts in large quantities, and we specialize in producing a wide range of parts in nearly any quantity you need.

The uniqueness of fourslide machining over other machining processes is found in the capability of adding tooling as needed. Since there are four slides, four different tools can be used simultaneously, creating a part that is perfectly shaped in seconds and is consistent from part to part. Thanks to the revolutionary method of fourslide machining, we can produce complex shapes quickly with less material waste, thereby reducing your overall cost per part. We pass the savings on to you, making it possible to produce parts that use more expensive materials in an economic manner, keeping you on budget.

Four slide products are produced rapidly with extreme precision making this option an obvious choice for industries including aerospace, military, lighting, agriculture, food production, and the medical field. Whether you need standard stainless steel clips or metal spring clips and clamps that require special customization, Wm Dudek Manufacturing has the efficient, cost-effective solution for your manufacturing needs.